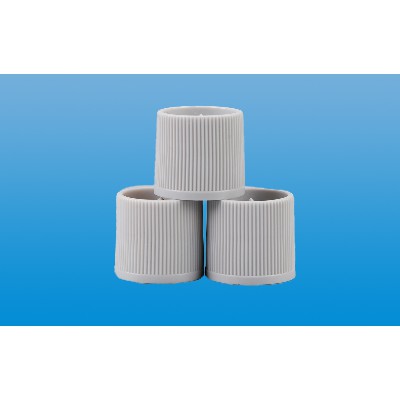

How to improve the sealing of medical bottle cap manufacturers

With the rapid development of the industry, the market competition of various medical equipment and packaging has become increasingly fierce. The variety and output value of various drugs have accumulated over the years, and the quality requirements for pharmaceutical aluminum-plastic caps used for packaging and sealing have become higher and higher. This is because to extend the useful storage life of drugs, medical bottle caps are required to achieve excellent sealing. So, how to improve the sealing of aluminum-plastic cover?

Although rubber has a good inductive function, because it contains non-rubber components, such as protein, acetone extract, ash, moisture, etc., its various functions can not meet the requirements of the sealed packaging of drugs, and its air permeability, water permeability and aging stability are not ideal, which is one of the main reasons for the formation of moisture absorption and metamorphosis of several water-sensitive preparations during the storage and use period.

In order to compensate for the defect that the raw material cannot be sealed due to moisture absorption and metamorphosis, the pharmaceutical factory has to use the non-opening aluminum cover, and then apply a layer of white wax on the outside after capping. This sub-packaging process is cumbersome, not only costs labor and materials, but also affects the beauty of the drug packaging.

For example, in order to improve the sealing and avoid the influence of rubber aluminum-plastic cover on the clarity of large infusion, a layer of polyester film has to be wrapped outside the aluminum-plastic cover to form a disordered packaging process in the pharmaceutical factory, which cannot form a one-stop flow line operation.

Article source: medical bottle cap manufacturer hit-fm.cn

-

11-29

Functions of medical aluminum caps of medical bottle cap manufacturers

1. Anti-theft identification cover is also called anti-theft safety cover; Anti-motion marks are also called anti-moving rings and safety rings. On the basis of the general screw cap, add a skirt arou

-

11-29

Four advantages of medical bottle cap manufacturers

1. The medical bottle cap has the advantages of simple structure and low cost, and the medical aluminum-plastic composite cap is universal in the world, with mechanical pressure sealing, very good sea

-

11-29

How to improve the sealing of medical bottle cap manufacturers

With the rapid development of the industry, the market competition of various medical equipment and packaging has become increasingly fierce. The variety and output value of various drugs have accu

-

11-29

Precautions for manufacturing process of customized pharmaceutical bottle caps of pharmaceutical aluminum-plastic caps

1. The pharmaceutical aluminum-plastic cover shall be made of aluminum alloy materials, and shall be cleaned after stamping, with the intention of removing the lubricating oil and dust coated on the a